OUR CAPABILITIES

Our internal capabilities highlight our potential to accommodate any machining requirements. Whilst our scheduling team ensures capacity is maximised and superb efficiency is maintained.

We also offer a wide range of sub contractual processes, including Plasma, TIN coating, grinding, Heat treatment and NDT. Our subcontractors are very reputable and provide a great service.

Ecoca SJ 35 CNC lathe

12″ chuck

Max part size 500mm dia x 1000mm long

Max bar capacity 76mm

Fanuc control

2 off

Doosan Lynx 2100LYSB CNC bar feed lathe

8″ chuck twin spindle lathe with c and y axis for milled features

Max part capacity 350mm x 500mm

Max bar capacity 65mm

Fanuc control

LNS servo bar feed

2 off

Goodway GCL-2 CNC lathe

8″ chuck single spindle lathe

Max part capacity 350mm x 600mm

Max bar capacity 51mm

Fanuc control

XYZ Prototurn SLX 1630

8″ chuck manual/CNC lathe

Max part capacity 250mm dia x 600mm long

Prototurn control

Emco Concept turn 105 CNC lathe

4″ chuck

Max part capacity 30mm dia x 100mm long

Fanuc control

Harrison centre lathe

XYZ 1500 milling machine

Delapena honing machine with air gauging

Myford cylindrical grinder

Jones and Shipman surface grinder

Estarta 301 centreless grinder

Weldlogic AWS-200N automated TIG welding system

6″ chuck, support centre, wire feed, camera monitoring system

2 off

Bridgeport TorqueCut 3 axis vertical mill

4th axis indexing system

Table size 750mm x 350mm

Heidenhain control

2 off

YCM NSV 66A vertical mill

5th axis add on unit

Table size 660 x 500mm

Heidenhain control

1 off

Doosan Puma MX 2000 ST

9 axis mill turn

Twin spindle

Milling turret with 40 tool magazine

Turning turret with 24 positions

Max part capacity 600 dia x 900mm long

Max bar capacity 65mm

Fanuc control

LNS servo bar feed

Doosan Puma MX 2500 ST

9 axis mill turn

Twin spindle

Milling turret with 40 tool magazine

Turning turret with 24 positions

Max part capacity 600 dia x 900mm long

Max bar capacity 76mm

Fanuc control

Dedicated temperature-controlled inspection room

DEA Global Performance CNC CMM with Renishaw probing

Mitutoyo surface tester

Starret light based CMM

Metric and imperial thread gauges

Wide selection of plug gauges

Wide selection of pin sets

Mitutoyo digital bore mics

Mitutoyo hand tools

Taylor Hobson roundness testet

Avery Denison Hardness tester

Range of microscopes for small part insp

Internal boroscopes with access as small as 1.2mm dia

Air gauging for internal bores with tolerances as small as 0.004mm

PMI Inspection service

OUR MACHINERY

Our purchasing team source high graded material predominantly from America and Europe, whilst using local distributors. We are striving to reduce our carbon footprint by using local courier services and minimising purchases made outside of the UK.

DOOSAN PUMA MX 2500 ST

CAPABILITIES

9 axis mill-turn machining centre that combines the ability of a twin spindle CNC lathe with the capability of a 5-axis milling machine. These machines allow us to load billet or bar into the main spindle, machine with a combination of milling and turning tools, automatic transfer over to the sub spindle and then continuous machining with milling and turning tools to produce a finished part which can be inspected on the CMM and then dispatched.

40 tool magazine capacity for the milling spindle, 12 driven tool positions on the turning turret, 12” chucks on both main and sub spindles, 76mm diameter bar capacity, 12 turning tool positions facing the main and sub spindles, Fanuc control system.

Equipped with Filtermist extraction system (maintained by SW testing) for the removal of coolant mist and fully interlocked guarding ensures high standards of operator health and safety.

DOOSAN PUMA MX 2000 ST

CAPABILITIES

9 axis mill-turn machining centre that combines the ability of a twin spindle CNC lathe with the capability of a 5-axis milling machine. These machines allow us to load billet or bar into the main spindle, machine with a combination of milling and turning tools, automatic transfer over to the sub spindle and then continuous machining with milling and turning tools to produce a finished part which can be inspected on the CMM and then dispatched.

40 tool magazine capacity for the milling spindle, 12 driven tool positions on the turning turret, 8” chucks on both main and sub spindles, 65mm diameter bar capacity, 12 turning tool positions facing the main and sub spindles, Fanuc control system.

Equipped with Filtermist extraction system (maintained by SW testing) for the removal of coolant mist and fully interlocked guarding ensures high standards of operator health and safety.

DOOSAN LYNX 2100LSY - 2 OFF

CAPABILITIES

Twin spindle high production CNC lathe with C and Y axis makes for a fast compact turning centre with the ability to produce complex milled features on a small scale. 65mm diameter bar capacity with LNS servo driven bar feeders allow for continuous production in a ‘lights out’ environment so that we can offer reduced leadtimes and costs to our customers. 24 position turrets can be kept fully stocked with tools to reduce set up times for all common turning applications.

Fanuc control system.

Equipped with Filtermist extraction system (maintained by SW testing) for the removal of coolant mist and fully interlocked guarding ensures high standards of operator health and safety.

ECOCA SJ 35 HT - 2 OFF

CAPABILITIES

Single spindle, single turret, 2 axis lathes. Super heavy duty machine with the ability to hold 0.005mm tolerance all day no matter what the materials. Used for all manor of work from 316 stainless steel castings to hard turning up to 65 Rockwell M340 steel. The flexibility of these machines replaces the need for many grinding applications and often gives superior surface finishes in a fraction of the cycle time traditionally required.

12 position turret holds all the common turning tools, programmable centre gives support for shaft work. Large spindle bore allows us to hold 3” diameter bar when required. Fanuc control system.

Equipped with Filtermist extraction system (maintained by SW testing) for the removal of coolant mist and fully interlocked guarding ensures high standards of operator health and safety.

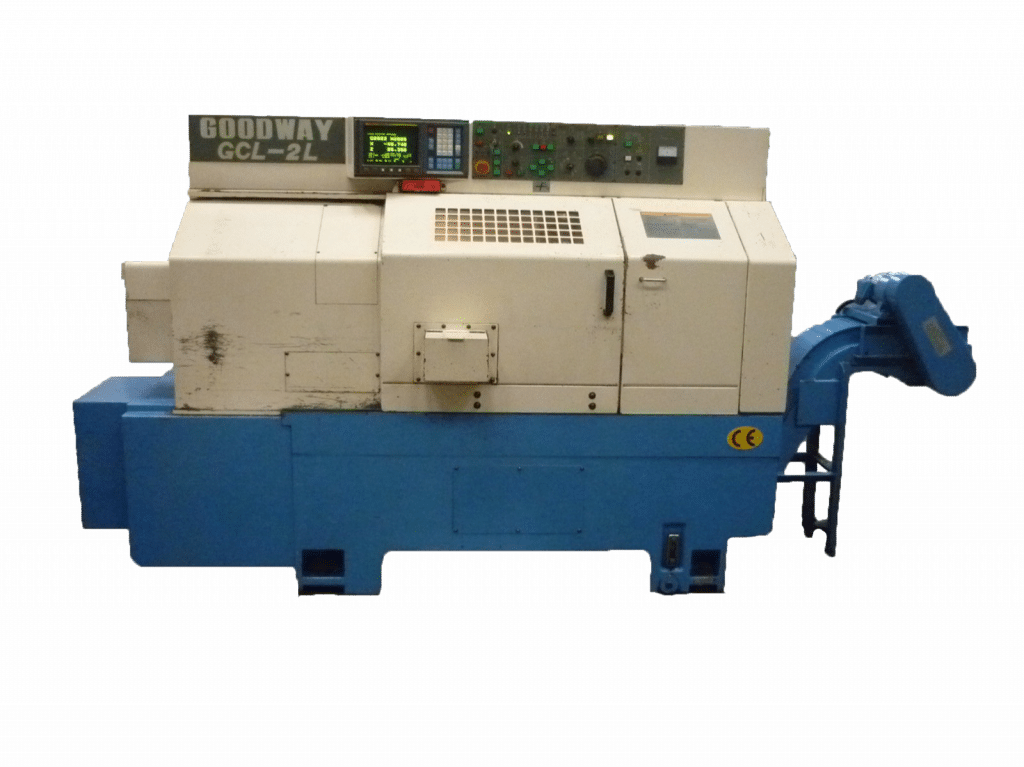

GOODWAY GCL-2

CAPABILITIES

Single spindle, single turret, 2 axis lathe. Basic but vital CNC lathe for second op work as well as straightforward turning when required. Equipped with Hainbuch work holding for quick change over and set ups as required. The hardened and ground slideways of this machine give us good reliable performance and solid cutting in the exotic materials that form the basis of our work.

12 position turret holds all the common turning tools, 50mm diameter bar capacity, Fanuc control system.

Equipped with Filtermist extraction system (maintained by SW testing) for the removal of coolant mist and fully interlocked guarding ensures high standards of operator health and safety.

XYZ PROTURN SLX 1630

CAPABILITIES

Semi CNC lathe with the ability to run as a manual machine or a low volume production CNC. Equipped with 8” chuck and 5C collet system for small bar and second op work. Using XYZ’s basic programming system allows quick program writing without the need for full CNC programming knowledge.

BRIDGEPORT TORQ-CUT TC3 - 2 OFF

CAPABILITIES

3 axis CNC mill with a working area 750mm x 350mm x 450mm. Used for a wide range of prismatic machining operations as well as machining of port detail in previously turned components. These Heidainhain controlled machines are quick and easy to use as well as being highly accurate for positionally close tolerance work. 22 position rotary magazines are backed up with large capacity tooling cabinets loaded with preset tools that can be changed over for quick set ups.

Equipped with Filtermist extraction system (maintained by SW testing) for the removal of coolant mist and fully interlocked guarding ensures high standards of operator health and safety.

YCM NSV 66A

CAPABILITIES

3 axis CNC mill but with an additional 3+2 Detron table mounted in the working area to give 5 axis positional capability. This machine is fast and powerful, 22kW spindle and 12,000 rpm. The 30 tool magazine is backed up with large capacity tooling cabinets loaded with preset tools for quick change over and set ups. We have the ability for high-speed precision milling in Aluminium and also heavy cuts in rough stainless castings. The machine has through spindle coolant, automatic tool probing capability and Renishaw component probe for in-cycle verification and part position set up. Heidanhain control lets us share programs across the milling section and utilizes the machines built in programming cycles for quick program generation.

Equipped with Filtermist extraction system (maintained by SW testing) for the removal of coolant mist and fully interlocked guarding ensures high standards of operator health and safety.

MANUAL MACHINING CAPABILITY

A range of manual machines and grinders to cope with small volume enquiries and post heat treatment operations as required. We are well versed in the range of post machining requirements that our customers need and have a trusted supply chain offering heat treatment facilities. We have cylindrical and surface grinders that are well suited to post treatment machining as well as the option for hard turning on the bigger components.